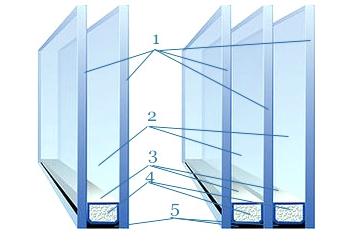

Multiple glass unit – translucent structures of two or more glasses, tightly connected to each other through a space frame. Multiple glass unit can be with two glasses (single chamber) and with three glasses (two-chamber).

1. Glass

2. Air Chamber

3. Spacer frame

4. Absorbent

5. Sealants

Glass

Glass determines the type of multiple glass unit:

Energy saving. Energy-efficient glasses are used in the production. Additionally, the glass can be filled with an inert gas in a mixture with air. The use of energy-saving glass and filling with argon can significantly improve the energy efficiency compared with common multiple glass unit.

Antinoise. We used laminated glass made with the use of special noise-reducing rubber. These glasses also acquire additional high impact-proof properties. To improve the sound insulation of glass there may also be used glasses with different thicknesses.

Sun-protective. We use glasses with special coatings which reduce the transmission of solar energy. These glasses can have different colour shades. These glasses are characterized by coefficients of specular reflection and light transmission.

Spacer frame

Serves for the creating of the insulating air (or gas) chamber. The width of the frame determines the thickness of the chamber. The coefficient of heat transmission of multiple glass unit depends on it. It decreases with increasing of the chamber thickness up to a certain point, and then begins to rise again. This means that for each fill (air, argon) there is an optimum thickness of the chamber in which heat transmission of the multiple glass unit is minimal. The cavity if the spacer frame is filled with an absorbent (molecular sieve). In most cases the frames are made of aluminum. We also use the frames with additional plastic coating (such as Termix), and that helps to reduce the heat conduction coefficient.

Absorbent

Absorbent in the multiple glass unit is necessary for the absorption of water molecules in the inner chamber of the multiple glass unit, which got there during the production process of multiple glass unit, and as a result of diffusion through the sealant. As the desiccant there can be applied molecular sieves, silica gel and a mixture of both products.

Sealants

Sealants in the multiple glass unit are needed to create a sealed chamber between the panes, which prevents the penetration of water molecules into the chamber and the gas leak from the chamber. This is achieved by two stages of sealing. Primary seal – it is polyisobutylene, which is applied prior to assembly of multiple glass unit on the outer edges of spacer frame evenly. Its main function – protection against the ingress of water vapor inside the multiple glass unit and gas leaks from it. Secondary seal is performed by two-component polysulfide, the primary purpose of which is to form strong elastic connection between the glasses and spacer frame at the molecular level. It also serves as additional protection against the penetration of water vapor and prevents leakage of gas.

English

English Latviešu valoda

Latviešu valoda Русский

Русский